The Effectiveness of Concrete Bollards – Protection and Security

The original bollards were crafted using massive tree trunks, or vertical cannon...

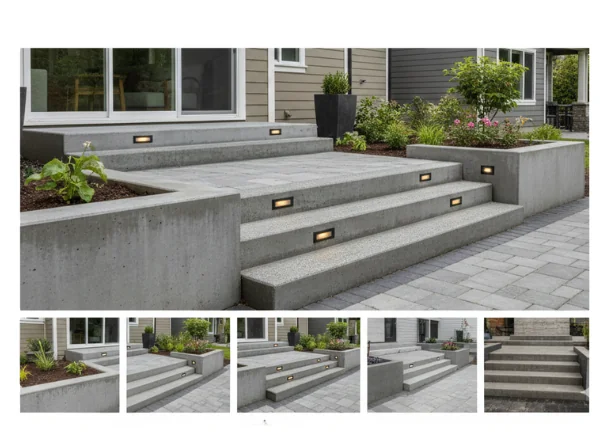

Whether you’re connecting your patio to ground level or integrating stairs into a new outdoor living space, concrete patio steps provide the durability, safety, and design flexibility today’s homeowners and contractors demand. This comprehensive guide covers everything from design considerations to installation methods, helping you make informed decisions for your next project.

With over 40 years of experience in precast concrete manufacturing, Sanderson Concrete has helped thousands of property owners and contractors design and install high-quality concrete patio steps that combine structural integrity with aesthetic appeal.

Not all concrete patio steps are created equal. The right choice depends on your patio layout, elevation change, architectural style, and project budget. Here are the most common types we manufacture and install:

Traditional concrete steps are straight, perpendicular risers that connect your patio to ground level or another elevation. These are ideal for:

When designing new outdoor living spaces, integrating stairs directly into the patio structure creates seamless transitions and maximizes usable space. This approach is popular for:

Design Advantages: Unified aesthetic, improved water drainage, structural efficiency, and increased design flexibility for custom layouts.

Wide landing steps (also called platform steps) feature extra-deep treads that function as mini patios themselves. These are perfect for:

• Creating gathering spots on sloped yards • Placing planters or outdoor furniture between levels • Providing rest areas on longer staircases • Adding visual interest to large patio expanses

Typical Dimensions: 18-36 inch tread depth (vs. standard 11-12 inches), allowing for comfortable standing and decorative elements.

Modern concrete fabrication allows for stunning decorative finishes that elevate your patio steps from functional to architectural focal points:

• Stamped concrete – Replicates stone, brick, or tile patterns • Colored concrete – Integrated pigments for long-lasting color • Exposed aggregate – Textured non-slip surface with visual depth • Bullnose edges – Rounded step fronts for safety and style • Inlaid borders – Contrasting materials for accent details.

Proper planning ensures your concrete patio steps meet safety codes, match your aesthetic vision, and provide decades of reliable performance. Here’s what to consider during the design phase:

Building codes exist to prevent accidents and ensure consistent quality. Key requirements for concrete patio steps include:

| Requirement | Standard Specification |

|---|---|

| Riser Height | Maximum 7.75 inches; all risers within 3/8″ of each other |

| Tread Depth | Minimum 11 inches measured nosing to nosing |

| Step Width | Minimum 36 inches for residential; 44-48″ for commercial |

| Handrails | Required for 4+ risers (check local codes); 34-38″ height |

| Slope | 1/4″ per foot minimum for drainage; 2% maximum cross-slope |

Note: Requirements vary by jurisdiction. Always verify local building codes with your municipality before beginning construction.

The foundation of your concrete patio steps is literally the foundation. Poor soil preparation leads to settling, cracking, and premature failure.

Soil type: Clay expands/contracts; sandy soils drain well but may need compaction • Drainage patterns: Water must flow away from steps and patio • Frost depth: Footings must extend below frost line to prevent heaving • Existing utilities: Call 811 before digging to locate underground lines • Vegetation: Tree roots near steps can cause long-term damage.

The Concrete patio steps should complement, not clash with, your home’s architecture and existing outdoor elements.

Your concrete patio steps should complement, not clash with, your home’s architecture and existing outdoor elements.

Choosing between precast and poured-in-place concrete steps impacts project timeline, cost, quality control, and long-term durability. Here’s how each method works and when to use it.

Precast steps are manufactured in a controlled facility, cured to full strength, then transported and installed on-site. This is Sanderson Concrete’s specialty and our recommended approach for most residential and commercial applications.

1.1 Advantages:

1.2 Ideal For:

Poured-in-place (also called site-cast or cast-in-place) involves building formwork on-site, placing rebar, and pouring concrete directly where the steps will remain.

Advantages:

Considerations:

Ideal For:

Understanding the installation process helps you prepare your site and coordinate with contractors. Here’s how professional precast concrete step installation works:

Timeline: Most residential precast step installations are completed in 1-2 days from site prep to final cleanup.

Pricing for concrete patio steps varies based on method, size, finish, and regional labor rates. Here’s a comprehensive breakdown to help with budget planning.

| Installation Type | Cost Range | Typical Scope |

|---|---|---|

| Precast Steps (Basic) | $800 – $2,000 | 3-step unit, standard finish |

| Precast Steps (Premium) | $2,000 – $4,500 | 5+ steps, decorative finish, railings |

| Poured-in-Place (DIY) | $300 – $800 | Materials only, 3-4 steps |

| Poured-in-Place (Pro) | $1,500 – $5,000+ | Full labor, formwork, finishing |

| Integrated Patio Design | $5,000 – $15,000+ | Multi-level patio with stairs built-in |

Should you tackle concrete patio steps as a DIY project or hire professionals? The answer depends on your skill level, available time, and project complexity.

DIY installation can save money but requires construction experience, proper tools, and significant time investment.

Professional installation ensures code compliance, structural integrity, and aesthetic quality—critical for steps that will be used daily for decades.

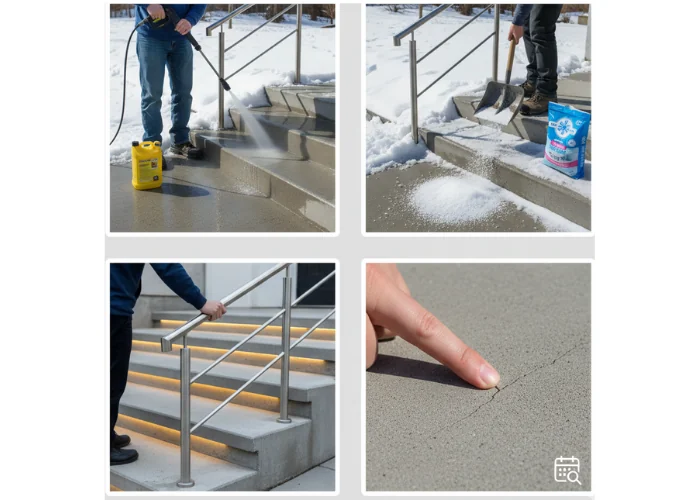

Properly installed concrete patio steps should last 30-50+ years with minimal maintenance. Here’s how to protect your investment and ensure safe daily use.

Annual Tasks:

Seasonal Tasks:

How many steps do I need for my patio?

Divide the total elevation change by 7 inches (standard riser height). For example, a 21-inch drop requires 3 steps. Always verify measurements with a professional before ordering materials.

Can I add steps to an existing concrete patio?

Yes. Precast steps can be anchored to existing patios using mechanical fasteners or construction adhesive. Ensure the patio has adequate thickness (minimum 4 inches) and isn’t severely cracked or deteriorated.

How long before I can use new concrete patio steps?

Precast steps are ready immediately after installation. Poured-in-place steps can handle light foot traffic after 24-48 hours but shouldn’t bear full weight for 7 days. Wait 28 days before sealing.

Do concrete patio steps need permits?

Requirements vary by jurisdiction. Most municipalities require permits for stairs with 4+ risers, structures over 30 inches tall, or commercial applications. Always check with your local building department before starting work.

What’s the best finish for outdoor concrete steps?

Broom finish provides excellent traction and is the most cost-effective. Exposed aggregate offers superior slip resistance and aesthetic appeal. Avoid smooth trowel finishes which become dangerously slippery when wet.

How wide should concrete patio steps be?

Minimum 36 inches for residential; 48 inches recommended for comfortable two-person passage. Commercial applications typically require 48-60 inches. Wider steps (6+ feet) create inviting entrances and can accommodate planters.

For over 40 years, Sanderson Concrete has been the trusted precast concrete manufacturer serving British Columbia, Canada and US. We’ve supplied thousands of concrete patio steps, retaining walls, utility structures, and custom precast elements to homeowners, contractors, municipalities, and commercial developers. Our facility produces precision-engineered products that meet or exceed ASTM standards, backed by our commitment to quality, reliability, and customer service.

Whether you’re a homeowner planning a backyard renovation or a contractor managing multiple projects, we’re here to provide expert guidance and quality precast concrete solutions.